In the previous Ti experiments, it was observed that adding a few percent titanium flakes to the propellant offered a very bright, sparkling tail. Problem is, much of the Ti would be released at the launch pad, not in the air.

So a method is sought to delay the emission of sparks until the propellant burn is partly over.

Three things are wanted here.

2. A nice sparkle to the burn, providing a dramatic visual effect

3. A short delay before the sparkle begins, to get the rocket up into the air and keep the crackling sparks off the dry tinder.

I had been thinking about loading the Loki 54mm motor with 2 Bates grains at the nozzle end, but placing an uncored solid cylinder at the head end to provide a slow burn for the duration of the rocket's ascent. This solution is so simple it's kinda dumb.

Dustin Brown on the SugPro list discussed using Ti in just one of the grains in the rocket motor, and still getting a good effect. He also mentioned the desire to delay the emergence of Ti sparks until the flight was well underway. Suddenly it dawns on me that all the grains do not have to be alike. I wonder if Ti placed in the smoke grain would make it out the nozzle? And since this is an end-burning configuration, could I place a "cap" of plain propellant over the Ti propellant to delay its emergence?

First Test - 3/6/04B

The grains used in these tests are Bates-type, 1.85 inches long, 1.3

inches OD, including inhibitor which is two turns of posterboard glued

on with epoxy. Pretty much like those used in developing the Sugar

Propellant Proposal for TRA. Core is made with a 3/8 inch wooden

dowel, yielding an actual core of about 0.4 inch diameter. Thus the

web thickness is about 0.4125 inch.

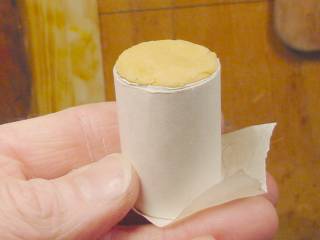

| The smoke/spark header grain is solid, no core, epoxied into an inhibitor tube. Thus it will be an end-burner. Length is 1.8 inches, OD 1.2 inches. The top end is inhibited a disk of high-temperature gasket material and a thick coat of epoxy. The first 1.55 inches of propellant contains 20% Ti flakes. Here I am placing the plain candy over the Ti propellant, and have a bit too much. |  |

| The last 0.25 inch was to be plain propellant, but I got generous and

rounded it over a little. Mistake. Didn't measure it either,

but am guessing it is about 0.35 inch down to the Ti propellant.

|

|

Making the unsafe assumption that the propellant would burn evenly on all exposed surfaces, then the sparks should fly about 2/3ds of the way into the burn. Such was not the case.

Static Test 3/6/04B

Click Here for a video of this test

(1.8 meg .mpg file, 7 seconds of video)

Not a bad burn, with a nice spray of sparks at the very end. It was almost like they had been held back somehow. Or perhaps those that emerged during the burn were consumed in the motor? Seems unlikely, but I have to test that notion!

Something else I had been wondering about - would this long-burning header grain overheat the casing? Especially since it is burning metal? Well the casing was too hot to hold right after the burn but not by much - I am guessing about 250 degrees. The paper wrapped around it was stiff, like a well-ironed shirt, but not discolored by the heat. The inhibitor tubes inside the casing were largely intact, and the case liner (two turns of poster-board) was not burned through at any point. So I will assume that the strength of this casing was not seriously compromised by this burn.

Second Test - 3/7/04B

So this time I start with the plain propellant. I actually broke

down and did the math to determine how much it would take to make a disk

1/8 inch thick, weighed out just that amount, heated it to 200 degrees,

and pressed it into place.

|

|

Then the tube was lightly coated with epoxy and warmed Ti propellant was packed in to almost-fill it. Since the epoxy was barely scathed in the first test, I am using just a thick layer to inhibit the top end of this one. Depth of this header is only one inch - I don't have any reason to make it longer at this point. I just want to see if it goes out after the Bates grains are exhausted. I have had that happen.

Static test 3/7/04B

Click Here to see a video of this test.

(2 meg .mpg file, 7 seconds of video)

This one did just about what I wanted. There were a few early

sparks, but the great rush occurred about 1/3 the way into the burn.

Followed by a nice sprinkling of sparks in the after-smoke. I am

wondering if these later sparks will be visible during a daytime launch.

Maybe this is where I should use the coarser Ti? Or wait for a night

launch?

Third Test - 3/7/04C

This one is very similar to Test 2 except that there is no plain propellant cap on the header grain. It is a one-inch solid grain with Ti propellant all the way. Purpose of this test was to see if this configuration somehow trapped the Ti in the motor. Test 2 pretty much eliminated that theory, but I have a motor ready and so must fire it!

Click Here for a video of this test

(1.2 meg .mpg file containing 5 seconds of video)

This one is pretty obvious even in the frame above. Note the sparks well above the smoke, evidence that the header grain is releasing its Ti right away, and that it has little difficulty getting out of the motor.

I still suspect that more Ti is consumed in this configuration that, say, if the Ti were placed in the last grain just above the nozzle. No doubt some of the smaller particles are consumed entirely, and the larger particles may be partly consumed before being ejected. I suspect this adds to the ISP of the propellant, but at the moment have no evidence. It may be trivial. But I suspect that finely powdered Ti can increse thrust substantially.

Conclusions:

A sparky/smoke header grain is feasible in this kind of rocket motor.

Sparks emerge with little apparent hindrance from the sparky sugar motor

On the other hand, all of these tests were at relatively low Kn ratios, and thus at low pressures. Things might work differently at higher pressure.

None of the header grains were extinguished when the propellant charge burned out. That is a good sign. In the past sometimes they have. I can put some Fe2O3 in the propellant to minimize this effect, but would rather have a slow-burning grain for longer flights.

Can't hardly wait until the next amateur launch!

Jimmy Yawn

jyawn@sfcc.net

www.jamesyawn.com