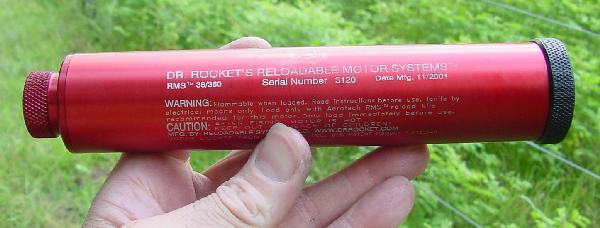

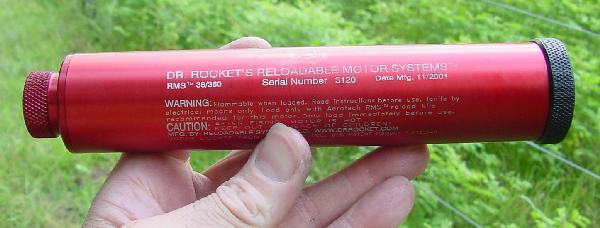

The Project: To develop a safe, reliable, and effective reload for Aerotech/Dr. Rocket motor casings using recrystallized KN/sucrose propellant.

The Process: To carry over techniques learned largely through my PVC-motor tests, and further refined in the cast-aluminum casings tests.

Procedures for making recrystallized KN/sucrose and for making Bates and other grain formations of this propellant. These processes are still experimental, and so further refinements will be illustrated here and there.

Motor casings and components are available from Aerotech and their distributors, and Dr. Rocket

Nozzles, O-rings, washers and other parts are available from RCS Rocket Motor Components

O-rings in quantity (and many other bits of hardware) are available from McMaster-Carr

"High Temperature Gasket Material" was purchased from

a local auto-parts store

Click here for a video of this test (716k, 4 seconds of video)

Observations: Strong, brief thrust. Burn time of 0.52 seconds is much shorter than anticipated. Post-firing examination of the contents of the casing revealed that the "inhibitor" was almost entirely burned up. This, plus the short burn time, suggests that these grains functioned as uninhibited grains for most of their burn. Thus it seems likely that the Kn ratios and pressures were much higher than predicted.

A large part of the inner case insulation was also consumed, but the

case seems undamaged.

Paper wrapped around the outside of the casing was hot and crisp, but

not discolored by heat.

Assuming the outside inhibitor failed immediately and grains burned uninhibited, the initial Kn ratio would be 338 and the maximum pressure would be in the range of 1400 psi. Thus this inhibitor failure serves as an inadvertent test of the strength of the motor casing. Further testing will endeavor to stay well under this pressure, partly by reverting to an inhibitor that is known to work.

Weights were placed on the see-saw at the rocket motor end until it tipped. 47 pounds were required to make it tip, thus the thrust of this motor must have exceeded that level.

Click here for a video of this test (828k, 5 seconds of video)

Observations: Good burn, nice and steady. Burn time of 1.041 seconds is close to expectations, indicating that the inhibitor worked.

Post-burn examination of case contents revealed that the inhibitors held up well. They were still sturdy cylinders, not badly burned on the inner surfaces. The gasket material seems to serve very well as case insulation, as the motor was almost cool enough to handle after the burn, and the material suffered no apparent damage. It emerged from the motor tube easily, in one piece, and with the head-end washer intact, and could have been used again.

Note that fulcrum is repositioned toward the motor end of the see-saw. At this point I was able to stand on it and barely lift the weight at the other end. Thus it would have required over 167 pounds of thrust to rock the stand, and this motor obviously did not go that high. Teresa commented that the motor would not have been enough to launch me, a statement with which I was compelled to concur. Then I wondered why she made that suggestion, and realized that "concur" means "with the dog." Subtle, that girl.

But note that the heavy board flexes a bit under thrust load. This brings back an old idea, and now I have the means to implement it!

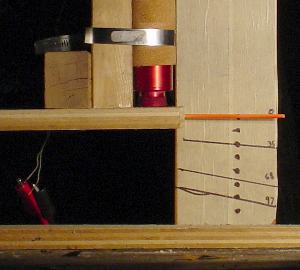

Trash plus camera makes:

Analog Test Stand

This version is a test of concept, to get enough experience that I might be able to build a "good" version. The angled lines represent the position of the orange pointer when weights are placed on top of the motor mount. Apologies for the wavy last line, but note that the last line, 97 pounds, was determined by the sum weight of 3 concrete blocks, balanced with one hand on top of the motor-mount while the other hand drew the line under their teetering mass. On the next one I will suspend a large bucket and add water for weight.

My Very First Thrust Curves

Video of 9/8/02c - 38/360 case with 3 Bates

grains, slightly regressive burn (500k file)

Excel spreadsheet file analyzing this test

Video of 9/9/02a - 38/360 with a single outside-inhibited

grain 5.75 inches long, progressive burn (500k file)

Excel spreadsheet file analyzing this test

29 similar tests have been performed to date. Here

are the rest them.

Jimmy Yawn

jyawn@sfcc.net

rev 11/30/02