Like a Woman Scorned launch video (17 meg .wmv file)

|

Jonathan prepares "Like a Woman Scorned" for launch. This rocket is

very nicely made, and light for its size. The dark marks are

residue from black powder ejection, as the body is unpainted

fiberglass, and thus translucent. Like a Woman Scorned launch video (17 meg .wmv file) |

|

The Sugar Rush was fired with a 4-grain Loki motor using Pixy Stix

rcandy. It had

Jonathan's extra-long head end closure, with a 2.3 inch

long rcandy smoke grain. Sims indicated that it would fly to about 5100 feet, and it has flown to similar altitudes with this load before. But the altimeter only read 2510 feet. I assume altimeter error, it was apparent that the rocket went higher than that. Sugar Rush launch video (13 meg .wmv file) |

|

Note the titanium sparkles, and the short section of dark smoke.

I believe this is where the smoke grain was compromised and it's

inhibitor failed. The only Ti in this motor was in the smoke

grain, and it was covered with a layer of KN/Epoxy/RIO to prevent it

from igniting too quickly. There should not have been any Ti

burning at this low altitude, so I know the smoke grain went bad

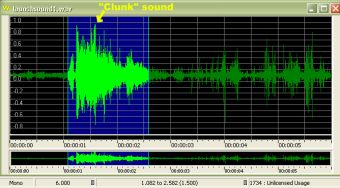

somehow. I believe the dark smoke is the epoxy grain burning. The case was damaged, the head end flared just past the c-clip. Also the nozzle washer was distorted and the nozzle cracked around its base. Clear signs of overpressure, fortunately not as severe as experienced at the February launch, although by a similar cause. Listening closely to the sound from Jonathan's video, I hear a "clunk" sound 0.61 seconds after liftoff, corresponding to the peak indicated on the wave graph. Looking at the video, I find some "curlycues" in the smoke trail which would have occurred at just about that instand. They look to me like a disturbance in the exhaust outflow. |

(Blue area is thrust time)

|

|