The Reload

Tidy packages for sugar propellant grains.

This page pulls together several techniques developed over the last few years

to produce sugar-propellant reloads for Aerotech - type casings.

An executive summary might read:

-

Make tubes: inhibitor and case liner

-

Make the propellant

-

Mold propellant into the inhibitor tubes

-

Insert grains in inhibitor tube

-

Seal with foil tape

Tools:

The only "special tools" one will need are two hardwood dowels. Lots

of other fiddly bits will be used as we go along, guess I should make a list

of them eventually.

Dowels: one 1-1/4 inch diameter for making the case liner tubes, and

another 1-1/8 inch diameter, for making the inhibitor tubes.

Find nice hardwood dowels, straight and reasonably round. Cut sections

about a foot long, and sand them nicely.

The larger dowel is for rolling case liner tubes, and is left unfinished.

The smaller one is for rolling inhibitor tubes. It is covered with

plastic adhesive tape, because it will be exposed to wood glue and we don't

want it to stick.

I am sure that metal or plastic rods could work just as well, but this is

what I have, and it works.

Duct Tape !

Another essential is Aluminum Foil Duct Tape. Note that this is NOT

the plastic kind! I am using Nashua 322 and Nashua 324A from Tyco Adhesives.

The only differences between these two that I can ascertain is that the

324A is 2-1/2 inches wide, 322 is 2 inches wide.

Also, that 324A has its name written all over it, but 322 is plain foil-colored,

much prettier! I wish the 324A did not have lettering.

This is incredibly useful stuff.

Inhibitor tube

Inhibitor tubes should be made first, as they need to dry a day or two

before using.

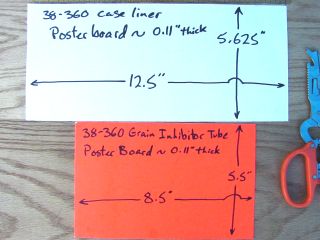

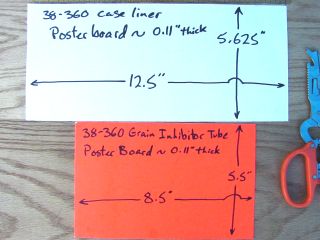

Obtain a piece of common posterboard. I am using Royal Brites # 24301 (white) which

measures 0.011 inch in thickness.

This is available at my local supermarket - the white board is $0.59 for

each 22x28 inch sheet.

Office Depot has them in packs of 10 for about $4.00

Colors cost a little more - I use them sometimes because I like them, and because it

makes the different tubes more apparent in these photos.

I begin by cutting a piece of posterboard 8-1/2 inches long by 5-1/2 inch

wide. Be sure to determine the bias of the board first, and cut so

that the bias is with the long side. Bias is the direction that the

board "wants" to roll. It will roll much more smoothly and easily in

one direction than the other. Usually, you can determine the bias by

simply rolling the board into a tube. It will be much easier one way

than the other, which will tell you the bias.

Some posterboard does not have a pronounced bias and doesn't like to roll

in either direction. Guess that is good if you are going to use it

as a poster and want it to lay flat, but it is not good for these tubes.

The board pictured below is of this type. It did not roll very

well. If you find your board is like this, do the best you can - it

is possible to make it work. But buy another kind next time.

Now we mix a little glue with water, roughly half and half. I usually

use Titebond wood glue. But Elmer's works fine, it's just a little

thinner so don't dilute it as much. Now that I say that...I forgot

it was Elmer's, poured in too much water and had to add more glue. Oh

well. It's cheap.

The glue/water should be mixed to a creamy texture, perhaps a bit frothy.

Slather it onto one side of the posterboard nice and even, roll the

board once around the 1-1/8 inch dowel, and be sure to "tuck" the leading

edge under the dowel. It will make a "squinch" sound and feel as it

tucks under the edge. Press and roll the dowel to roll up the rest

of the posterboard.

What do I mean by "tuck" and "squinch"? Here are a couple of photos:

First one is untucked. Second one is tucked. Work your fingers down

to where the action is to make sure the leading edge is well tucked before

continuing the roll. Otherwise, it will be oversized, and may have

delaminary gaps. Click here for a movie

of "the squinch." It is the clicking noise you hear as I am tucking

the ear under.

Let the slathering begin. Remember I said to "obtain" posterboard? I

suggest buying it, and usually do. Money tends to facilitate these

kinds of transactions. In this case it is only a little money, so be

generous. But this particular posterboard was obtained. I saw

it lying around in a classroom for weeks after the the presentations on that

topic were done. When Winter Break came and we did a little classroom cleanup, it was fair game and I absconded

with it. Hee hee hee! I love Education!

Secure the newly-rolled tube with several rubber bands, slide it off the

dowel, and stand it on end to dry. If you lay it flat, it is likely

to dry in an elliptical shape.

It's not a bad idea to wipe the glue off the dowel before starting another

one. I have ruined more than a few strips of posterboard by gluing them

to my stick.

I use the disposable foam brush not because it is cheap, not because it

is convenient, but because it is the best brush I have found for this purpose.

And you don't have to throw it out - just wash it well before the glue

hardens and it will be as good for the next round. You can just throw

it in the washing machine with a load of towels, but don't let the S.O. see

you do it. And you had better be the one to get it out too.

That tube needs to dry for a day or two. But if you are in a hurry,

let it dry for an hour and then put it in a low, low oven, perhaps 150 degrees,

and leave it for another hour. That should dry it fairly well. Bruce

Clemens says he puts them in the microwave for a few seconds to set the glue.

I haven't tried that yet, but will!

Case liner

This is also made from posterboard, but it does not need to be glued. Instead,

it is wrapped with the aluminum foil tape mentioned above. I am using

a different color in these photos so that it is easy to tell which tube I

am working on. In practice, the color matters only in that some of

the colored boards are a bit thinner than the white ones.

Cut a strip of posterboard 5-5/8ths inches long by 12-1/2 inches wide. Again,

cut across the bias so that it will roll easily the long way. Cut two

strips of Nashua 324A, each about an inch longer than the strip is wide, say

7 inches.

Twelve and a half inches is enough to circle the inside of a 38mm motor

tubing three times, with just a little overlap.

I find that two thickness is usually enough, three gives us a bit of insurance.

The tube is rolled, and the end trimmed to leave about 1/4 inch tape all

around. The dowel is used to press the tape nice and square, getting

ready for the next operation.

Note that one end of the larger dowel is tapered. The last 1/8 inch

or so has been sanded to a 45 degree angle, making a truncated cone. That

is to assist in this pressing procedure, to ensure an even squeeze.

Insert the tapered end into the tube, pressing the edge of the tape back

against the tube wall. Do both ends, slide the tube back on the dowel

and roll it on the table a time or two. Remove the dowel and notice

what a pretty crimp has been made. Nice, smooth, even, O-ring-supporting

edges.

Making the Grain

Because of the different sizes of dowels used in making the two different

tubes, they are matable. The inhibitor tube slides into the case liner

tube with little effort, but also with little wasted space.

Here we are getting ready to make the propellant grain. It will need

to happen quickly once started, partly because I am impatiently using 5-minute

epoxy. Also because it is a chilly today in our "Winter Wonderland"

and I am out in the breeze. The propellant is heating in the toaster

oven at 200 degrees, but once out it will cool very quickly. This batch

has 1 percent Ti added, so it will look a bit dowdy, gray and grainy. But

wait until you see the exhaust plume! It is also a slow-burning batch

of toaster-oven propellant, but that reeks of another experiment.

OK, here is a heads-up on how things will go together.

The case liner will serve as a support for the inhibitor tube while

we press soft propellant into it. The inhibitor tube will be coated on the

inside with epoxy before the propellant goes in.

The liner will hold a 1-1/4 inch "fender washer" which has a .281 inch diameter

hole in the middle of it. The dowel you see is our coring rod. The

end has been sanded to a point, then most of the point sanded off to make

a short truncated cone. The cone is then pressed real hard into that

washer to make a little shelf. This will serve to keep that end of

the coring rod centered while we press in the propellant.

Note once again that the inhibitor tube fits nicely into the liner. But

before it goes in, we must coat the inside of the inhibitor tube with epoxy.

Epoxy? Why? That seems like an awful lot of trouble...

Why? To make the propellant stick! Candy propellant will often

stick to paper products, but not reliably. Yeah, I know - some people

cast directly into the paper with no glue and get away with it. But

they are usually using a melt/cast propellant which may well be stickier than

mine. So if it's important, I hedge my bets and glue the tube.

Topside of the washer is greased before inserting into the liner tube. We

don't want epoxy sticking to it, or propellant!

Make a tool. Take a section of doweling at least 8 inches long, cut

a strip of paper toweling, wrap tightly around the end and secure with a

rubber band. This is the epoxy swab. Here I am dancing it in a

glob of 5-minute epoxy, about 1/4 teaspoon. It doesn't take much, just

enough to get a complete, even coating inside the tube. I move the

swab around and around, then back and forth, then around again and look at

it.

That looks good! If you see any dry spots, big globs or struggling

insects, feel free to take corrective action. Small insects can stay

in the tube. They will probably die from the epoxy coating anyway,

since insects breathe through their carapace. Might as well go in a

blaze of glory. Large insects should be removed. They might reduce

ISP.

Now the coring rod has been dipped in water (yes, water!) and wiped off.

This is the mold release agent that will allow the rod to be withdrawn.

It is environmentally friendly, cost-effective, and it works. Please

do use it.

Flash forward, November 2005:

I have since realized that Vaseline works much better than water.

Vaseline is more persistent, and does not moisten the grain.

Now I am recommending this finger-friendly grease as the coring

rod release agent.

The propellant patty is out of the oven, the epoxy is starting to cure...

it's showtime!

A chunk of propellant is cut off with a table knife, and formed into a "snake."

Snake is slithered around the tropical hardwood dowel and eased into

the tube.

The warm, soft propellant is packed to the bottom of the mold with a slender

stick. If the propellant sticks to the stick, stick the stick in some

water and wipe most of it off. That should end the sticking for a few

pokes.

When you get to the top of the tube, you might notice that the coring rod

isn't perfectly centered at that end. Not to worry. Just press

the propellant DOWN on the near side to move the stick toward the middle.

That will make a little crater, so press in another little blob of

propellant to bring that end of the grain up level.

Side note: I didn't do it here, but using a poking stick one web-width

in diameter will help to keep the coring rod centered. In this case

the web thickness is 3/8ths inch, same as the diameter of the coring rod.

Is that a coincidence or what!

To make the top-end grain pretty, I press another 1-1/4 inch washer down

on that end. This washer has a larger hole, about 1/2 inch. I

hope one day to obtain some washers with a 3/8ths inch hole so they can be

used for centering as well.

Now before you walk off, be sure to give the coring rod a twist to break

it free from the propellant. If you don't do it now, you may have a

heckuva time doing it later.

At least with rcandy, if the rod gets totally stuck you can just put the

whole thing back in a 200 degree toaster oven, soften the propellant, and

remove the stick. You will probably have to remake the grain, but can

recover the propellant. On the other hand, this stuff is cheap, and

a grain with Ti in it would make quite a sparkler, don't you think? And

the coring rod would make a good handle....

Cooling of the grain is patiently supervised by Mr. Buckley.

As dawn breaks, the new grain emerges from its casing. This grain

could be fired as it is for a progressive burn, and I am tempted...

But I have an experiment in mind, and so will cut it into three equal sections.

You were wondering about the chef's knife, weren't you? It's one of

my favorite tools. The inhibitor tube is marked into exact thirds, the

casing is scored all the way around, and the knife blade rolled around and

around until the inhibitor is cut completely through. The grains can

then be broken off by hand. Yes, the ends are a bit uneven, but I don't

think it matters a whole lot.

Wanna see some action? Here is a video of me breaking up that grain:

<><><>

Grains get dropped into the case liner tube. Here is the experiment.

I am placing squares of black match paper between the grains and at

the ends. I suspect this will improve ignition by spreading flame at

the grain junctions more readily than would be spread by the propellant flame

itself.

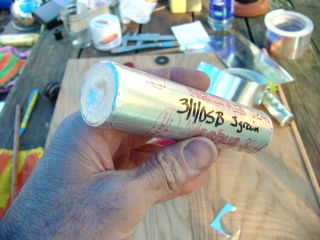

All three grains are in, time to seal up this package. Note that the

case liner tube is now slam full. Doesn't that warm your heart? I'm

cutting another piece of foil tape to cover one end.

Might as well put a piece of match paper at the ends too, else the tape might

be a problem. This foil tape serves as a mediocre inhibitor. It

works very well by itself in model rocket

motors, moderately well in 29mm motors, and not very well in 38mm motors.

I haven't tried it in my 54mm motor, and probably won't. But

sticking this tape directly to the end of the grain might delay or even prevent

its ignition. The match paper keeps the tape off the grain, and should

spread flame. Maybe I should have cut it round to fit better. Darn!

Another experiment!

The tape is hand-pressed onto the liner tube.

Hand pressing leaves some folds and gaps, so a motor casing is used to swage

the tape all the way flush. It works pretty well - what a handy tube!

Then I roll the package a time or two on a flat surface to even things

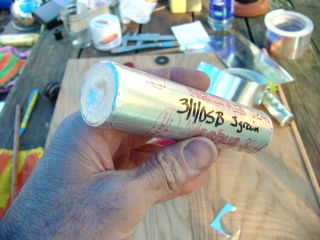

out, and it is done!

The finished load a thing of beauty. It should be airtight, watertight,

spark resistant, loyal, trustworthy, and brave. I imagine that the

propellant will keep inside one of these for a long time. Just how

long? Well, I need to do some tests on that issue.

Loading the motor casing

Here are some photos of a load I made and fired a few days earlier. Click here to see details

of this test.

The load is placed in the motor casing with its end-seals intact, thus the

propellant is still sealed from air until the moment the ignitor needs to

be inserted.

The forward bulkhead and nozzle assemblies still need to be installed. It

is hoped that some of these parts can be included in the package at a future

date.

The tube remains sealed inside the motor casing. If needed, it can

be removed from the casing without breaking the seal.

But if one were using a delay-grain in the forward bulkhead, it might be

a good idea to poke a hole in the forward end of the package before loading

it in the casing. Then again, the propellant does not seem to have

any problem burning through that one layer of tape, and the tape would ensure

that the delay grain was ignited by the motor, not by the ignitor. This

may require some experimenting!

Test Firing

Here the motor is placed in a test stand, and I am about to make a hole in

the foil so the ignitor can be inserted. The pointy thing is a chopstick.

Very useful things, chopsticks. Besides providing us Americans

with humorous dining experiences, they can be used to poke and prod where

fingers don't easily go. This one has a little epoxy on the end because

I used it to mix the stuff once. And it reinforced the tip pretty well.

In this experiment, I ran the pointy thing all the way down the motor, to

make a hole through each of the little pads of black match paper.

The Test

Click Here for a

video of this test

(900K .mpg, 3.5 seconds of video)

Click Here for an

Excel spreadsheet describing this motor's performance.

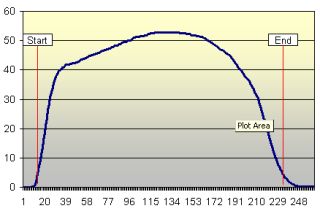

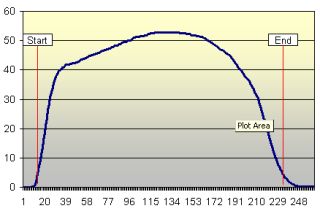

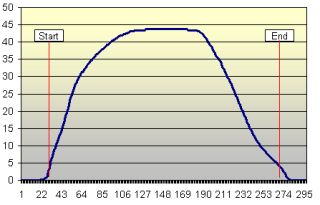

Hey! I'm not used to getting pretty thrust-curves. I need to

try that again

Another Test

3/5/05 - Similar test using even-slower burning propellant

(no photo yet - it's getting developed.)

Click Here for the

Excel spreadsheet on this motor test

That's not too bad either. I suspect that the black match paper is

helping to get the grains going by providing a strong ignition source between

the grains. Otherwise they may lag behind, generating a progressive

thrust curve when the burn should have been "neutral." Check out my

tests page for these.

Autopsy

Quick Quiz: What item was missing in my assembly photos?

Answer: Aerotech users got this one 100% - It's the fiber washers

that protects the O-rings from exhaust gasses.

And guess what? You don't really need them in these loads. The foil

tape apparently provides enough protection for at least a 38-360 firing. Note

that the nozzle-side O-ring is not badly burned. Under a microscope,

the O-ring shows a few shallow zorched spots, but nothing mission-threatening.

It could be used again. I have seen much worse burns with commercial

Aerotech reloads and washers.

The inhibitor tubes are burned away at the ends, but that is to be expected.

They are intact in the middles, which is to be hoped. The thrust

curve suggests good inhibition.

Case liner is burned somewhat. The first layer of posterboard is about

50 percent burned away. The second layer is about 1/3 gone, the third

layer is almost entirely still there. It has a scorch-mark here and

there, but has not allowed burn-through at any point. The aluminum-foil-tape

covering is completely intact.

The motor tube needs little cleaning. Soaking in water and a wipe

inside and out is generally adequate. But I have found some buildup

of sticky stuff inside the 360 motor casing, probably glue melted out of

the foil tape. It is soft, so probably not epoxy. WD-40 cleans

it off with a little scrubbing.

One more test

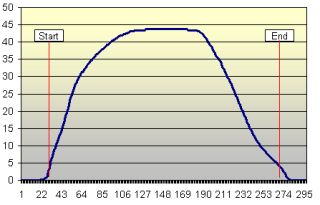

Oh, here is today's experiment. Essentially the same thing but using

the 38-480 casing with four Bates grains.

Click Here

for the Tests page, containing an analysis and video of this test.

The motor performed well, but the thrust curve was truncated by my leaving

the INA125 amp at too high a gain level. That needed to happen at some

point, I had to prove that one needs to reserve some headroom in these tests.

That will teach me. Well, probably not much.

Again, liner held OK, case cleaned up with a rinse and a wipe. Mid-H

performance despite the flat top curve.

This page is submitted for amusement and enlightenment purposes only. Any

other use is strictly forbidden by some law, somewhere, no doubt.

Comments, criticisms, additions, and bad jokes are welcomed!

Flash Forward!

September 5th, 2005

After four months of Florida swelter, I pulled out a "tidy package" moonburner load I'd

made for launch back in June but did not get a chance to fire. It has

been sitting in my magazine since it was made on 6/5/05.

I decided that it was time to fire it. I expected it to be all

gummy because the 54mm loads I had assembled back then had a thick coat of

goo, despite being "sealed" inside their commercial paper/phenolic case liner

tubes. Somehow they had leaked a little moist air. I scraped

off the soft stuff down to hard propellant, and they worked OK.

But this one, when opened, was crisp. No trace of moisture, no gummy

stuff. It was as dry as the day it was made! I fired it as test 9-5-05B, and its performance is nominal.

Now this is just one test. I have not yet done quality-control sampling

of this technique, but the fact that it worked once suggests that it might

work again, perhaps reliably.

Recrystallized Rocketry

home page

Jimmy Yawn

3/7/05

rev. 12/10/05

jyawn@sfcc.net