Improved Sugar Syrup Propellant

As good as recrystallized?

Forget the microwave! That

notion was just too inflammatory (pun intended) even though the way

I was doing it was "perfectly safe." Well, the only time I am perfect

is when I am a perfect idiot, so we will abandon the microwave approach

for now.

Besides, the Coleman stove is much more fun.

If you have never had the joy of using one of these incendiary devices,

please do yourself a favor and buy one at the next opportunity. It

allows one to cook virtually anywhere. Mine rides in the back of

the truck, just in case. That is where it acquired its charming "rustic"

look.

Besides, the Coleman can be taken out on the picnic table, a safe distance

from family and liabilities.

Herein lies virtue #1 for the sugar syrup process. Recrystallization

requires an oven. Ovens are invariably found in kitchens. Kitchens

are found in domiciles, where the production of rocket propellant is not

generally accepted.

So for about $50.00, the Coleman stove is a bargain compared to having

an oven installed in the workshop.

Another $41.00 advantage: Syrup works well with fertilizer-grade

KNO3.

Here is my bag:

From: Atlantis Hydroponics

50 lbs KNO3

Cost for fertilizer: $19.95

Cost for shipping: $21.00

But even with shipping, the cost is less than $1.00 per pound.

This stuff is difficult to use with the recrystallization process.

I have had some successes, so I know it can be done, but also some failures.

Recrystallization prefers high-purity KNO3 and this fertilizer obviously

has other stuff in it. Blue dye, for instance. We will see

that shortly. Turns into brown dye when heated, which we shall also

see.

So add to the list of virtues: very

low cost. Incredibly, shamefully, embarrasingly, perhaps dangerously

low cost. Since sucrose is only about $0.40 per pound here, and Karo

Syrup about $2.00 for a 16-ounce bottle, the materials price of a pound

of this propellant will be about $0.80

But the materials cost is negligible for experimental rocketry, even

when using the higher-priced chemicals.

<rant mode on>

Let it be proclaimed far, wide and loud,

that "saving money" is NOT a good reason to do experimental rocketry!

If you simply want to fire your rockets, stick to commercial motors.

They will cost less in the long run, the short run, and every run in between.

Then again, low cost can be a tempting rationale for justifying your

experiments when the S.O. makes nosey inquiries about how much of the family

budget is being spent on rocketry. One can proudly proclaim:

"For two bucks I can make enough propellant for a J motor! Four dollars

is a K, eight dollars is an L... and look how much the kid's little Estes

motors cost! Almost $2.00 each!" Ignore the look, if you can,

and resist the urge to display the receipt of your last purchase from a

motor vendor. That might be truly inflammatory.

Extreme caution is advised in utilizing this rationale.

If you believe it, it is a delusion which will be quickly pointed out to

you. If you don't believe it, it is a lie and will soon be recognized

as such.

Carefully skirt any reference to the workshop you had to build or remodel,

the kitchenware that has somehow migrated to your lab, the power tools,

or the zillion fiddly things you had to buy, make, or improvise.

Do not even glance at the sugar dish on the counter while engaged in this

conversation. If you are compelled to check its contents, grab a

cup of coffee first, and use a spoon, and don't forget the creamer - that's

a dead giveaway.

Avoid comments that might shift attention to the hours you put into

rocketry that might otherwise have been devoted to income-generating activities

or home improvement. Hope that the dishwasher and clothes dryer are

working OK, and that you are caught-up with all maintenance requests.

Try to move toward some useful non-rocketry object you have made or repaired

in your lab. Lean on it if you can.

At all costs avoid being drawn toward topics related to risk

of accidental injury or property damage - events of potentially infinite

cost. This is the anit-rocketers trump card. Prospects of medical

fees, liability, and even legal fees might be brought into play.

Consider but do not mention the possibility that your activities might

frighten the neighbors, their kids, or house pets. Fear is incalculable,

thus its social costs are presumed infinite. No doubt the S.O. is

thinking about all these things, which are always in the back of an experimenter's

mind. Bring them to the fore when doing experiments, but do your

best to keep them out of this conversation.

Have that conversation with yourself first. Do your experiments

justify themselves in terms of total costs and risk?

If your primary justification is low cost, the answer is "NO."

Experimental rocketry does not save money.

It is one of the more entertaining ways to waste money.

Done rightfully and carefully, its educational and inspirational value

makes it worth the risk and cost.

So for now, let's assume that all of the known costs are tolerable,

and all of the risks reduced to an accepable level by adequate planning,

preparation, knowledge, dilligence, safety equipment, good relations with

the neighbors, and insurance coverage. We will also assume that the

S.O. is satisfied with what you are doing and how you are doing it, and

that your neighbors are either accepting of your activities, or far, far

away.

Thus we may proceed.

</rant>

Downside for the sugar syrup process:

It requires that the KNO3 be ground to a fine powder. That can be

a pain. I ground some in the blender, which was a chore. Some

was ground in the coffee-mill as per Richard Nakka's recommendation.

That worked pretty well but my mill will only process a little bit at a

time.

Here I am pestering some into a powder in my mortar:

That works too, but the fun wore off pretty quickly.

Downside II: The resulting propellant

seems a bit more brittle than recrystallized stuff. This may be due

to the reduced water content, which I plan to test sometime soon.

Another virtue of this process is that it

does not require the hot-kneading of baked propellant flakes to make a

pliable "dough." The mixing is easily done with a wooden dowel.

Finally, enough of it is powdered to make a small batch of propellant.

| Here is the recipe

In one small saucepan, place:

100g KNO3, ground to a fine powder

In another little pan, place:

50g sucrose, granulated sugar.

20g corn syrup

1 teaspoon water |

Alternate recipe - if corn syrup is unavailable

Pan 1:

100g KNO3

Pan 2:

30g sucrose

30g dextrose

1 teaspoon water

Tested on 12/30/03, this recipe worked very well! |

The KNO3 is in the little green pan to warm over the secondary burner.

I fear that if it is cold, it will cool down the sugar syrup mix too quickly,

and mixing will be difficult if not impossible. So far, mixing has

been easy with warmed KNO3.

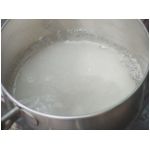

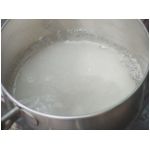

The sugar, corn syrup, and little bit of water are placed in the other

pan. I am using a stainless steel pan for the sugar mix so that color

differences will be more apparent. The color of the syrup is one

indicator that it is "done" and ready to mix.

Now the watched-pot syndrome ensues. The sugar mix is placed

over a medium-heat burner, and stirred to get all the sugar wet.

After a minute or so, it begins to bubble and clarify a bit.

And let's not ignore the KNO3, either. It is heating on the auxiliary

burner, which always burns a bit lower than the main burner on a Coleman

stove but that is good. We don't want to overheat the KNO3, especially

not to melt it, which is quite possible on such a stove.

The syrup has cooked until clear. Continue a little more until

it just begins to turn color. Can you see the slight shade of brown

in the right photo? It is more apparent in real life than in this

photo, but the instant you see any of the reddish-brown caramel color appear,

take it off the stove and mix in the KNO3.

A candy thermometer is on my list of things to buy. That should

allow more precise cooking, I think, and give an objective measurement

others might follow. Downside is that such a thermometer seems unlikely

to work with such a small batch.

| Time warp! Jump ahead to 12/30 and the batch made

with sucrose/dextrose. I recalled a trick Mom showed me when making

"white mountain" cake frosting, which I requested whenever the opportunity

presented. Stir the syrup. Hold up the spoon and watch

the drops fall. When a falling drop spins a long, fine thread, the

syrup is done. This worked very well on the sucrose/dextrose batch,

yielding a slightly-moister, less-brittle propellant. |

Now the gloves and face-mask go on. This is the most risky part

of the process, in my opinion. Up until this point, there is no "propellant,"

so the danger is small. Upon mixing, this becomes a pyrotechnic mixture

and if ignited somehow will produce a large flame very quickly. If

it ignites on the bottom, it may throw burning sticky propellant out and

onto whatever is nearby, including the mixer! Not to scare anyone

away, but here is where the danger is and you must be prepared to deal.

Let's add one more virtue to the list. The syrup process

gets around the problem of scraping up flakes of hot dried propellant,

which is a necessary part of the recrystallization process. I consider

scraping and mixing these flakes to be the most dangerous part of that

process. The flakes are very fast-burning, and could be explosive

if contained. Here we must mix, but avoid creating this more-hazardous

intermediate form..

Once it is mixed into a blob, the greatest danger is over and the gloves

can come off. There are those who will argue that gloves must always

be worn when working with propellant. Please don't yell at me, you

may be right most of the time, but not now. One valid concern is that most

amateur/experimental propellants contain toxic substances and so skin contact

must be avoided. This propellant is made from non-toxic, even edible ingredients,

so moderate skin contact is OK. If there were to be an accidental

ignition, the worst likely injury would be a minor blister. But there

are times where safety equipment poses more hazard than safety. Good

habits and good judgement must work together.

Gloves provide little safety and much inconvenience at this point.

If ignited, the propellant will burn quickly, but not so fast that one

cannot react. Secondly, this propellant is not very sensitive, not

prone to spontaneous ignition, and in fact takes a bit of roasting to get

it to ignite. So be wary of any possible ignition sources, and remove

them or remove yourself from them.

Here is today's blob. Nice color, don't you think? It looks

familiar.

I have seen that color before...

Quick quiz: Which bath soap is this color?

[ ] Lifebouy

[ ] Safeguard

[ ] Zest

[ ] Dove

Highlight the blank space in this box to see the answer:

None of the above! It is a trick question.

Zest is the only bar that comes close in color,

and it is NOT SOAP.

It is a detergent bar. |

Back to work! There are

Two tests to perform, burn rate and snap

test.

A bit of warm propellant is taken from the pan, rolled into a strand

about 1/4 inch in diameter, and allowed to cool.

A pinch is taken, rolled into a pea and mashed flat on the cool pie

plate.

After a minute's cooling time, the sample is bent in the middle to test

its texture. This batch snaps sharply, suggesting that it is plenty

dry, perhaps too dry. It will be on the brittle side. I prefer

for the sample to bend just a little, as I believe that a little residual

moisture preserves some viscosity which yields a tougher propellant, grains

that are less likely to break.

A piece of the strand is broken off and measured. This strand

is about 1-1/16 inches long.

Click Here to see a video of this strand burning

(1.4

meg file, 15 seconds of video, much of which is wafting smoke)

Length of strand: 1.0625 inches

Time of burn: 5.99 seconds

Burn rate at 1atm: 5.6 seconds per inch! This is

perhaps the fastest burn of any uncatalyzed KN/sucrose I have made.

I normally consider 8 seconds/inch "fast" and generally approach 5

seconds only with Fe2O3-catalyzed propellant.

Something is funny here...

As I watch the last wisps of smoke waft away,

I roll another strand, this one precisely 1 inch long

Let's watch it burn:

Click Here for a video of this burn (1.4

meg file, 15 seconds of video)

Strand length: 1 inch

Burn time: 8.04 seconds

Burn rate: 8 seconds per inch

That is more like it. Still pretty fast, but within bounds of

the known universe.

Other tests show similar burn rate, so here is my guess as to why the

first was so fast...

First strand was rolled from propellant that was just out of the mixing

pot, where it had been stirred briskly for a minute or two. I suspect

that there were air bubbles trapped in the propellant at that time, so

the first strand was a sort of "foam." Subsequent rolling and kneading

of the propellant allows the trapped air to escape, returning the propellant

to a more normal burn rate.

Results so far,

The Process: Except for the grinding

of KNO3, everything is simple, easy, and seems fairly safe. There

may be a ball mill in my future...

The Product: This versions seems pretty darned good.

I will be surprised if it is not equal to or maybe even better than recrystallized

KN/sucrose. It is a bit too brittle for my taste, but I believe that

leaving a bit of residual moisture in it will make it tougher, like rcandy.

Next...

I want to see if this process can be done without corn syrup,

perhaps by using a combination of sucrose, dextrose, and perhaps fructose

to simuate corn syrup. This could be useful to those who live in

countries where corn syrup is not common. The answer: Yes it

can! See "alternative recipe" above.

Static tests and perhaps flight tests to determine if this propellant

is equivalent to recrystallized propellant. It has worked OK in some

model rocket-sized motors, but not anything substantial, or on a test stand.

James Yawn

jyawn@sfcc.net

12/30/03